A blower is a machine which is mainly used to generate the flow of air at a substantial pressure. American Society of Mechanical Engineering (ASME) has defined blower “as the ratio of the discharged pressure over the suction pressure”. The main function of a blower is to increase the velocity of air when passing through equipped impellers. All manufacturing industries including power, petrochemical, oil and gas, mining, food and beverage, water and wastewater management industries need a high-quality blower service. These manufacturing industries need a blower for various purposes such as for exhausting, cooling, conveying, aspirating, ventilating, etc. In many industries, the blower is also called as Centrifugal fans.

[tmh_article_ads]

The blower is highly used in industries when it is necessary to use the moderate pressure that means when the industry needs that amount of pressure which is more than a fan but less than the compressor. Nowadays some companies have come up with turbo blower which is much more efficient than that of the traditional blower.

Types of Turbo Blowers

The following are some of the essential types of Turbo Blowers and you can choose any of these types as per your necessities.

- Geared Turbo Blower

A single stage geared turbo blower ranges from 50 to 6000 HP and it is highly aerodynamic efficient through the complete flow range. It is a kind of oil-free compression which mainly comes up with a constant speed. It also has a sleeve bearing which enhances its longevity. It has low operating and cost and requires minimal maintenance. It also comes up with API 617 complaint options.

- Gearless Turbo Blower

A single gearless turbo blower ranges from 20 to 1000 HP. These types of gearless turbo blower are 20 to 40% energy efficient. It produces less noise and normally uses one-third of the floor space of the existing technology. It does not need any kind of lubrication and you only need to change the filter after a specific period of time. Thus, it has a low maintenance cost. Its installation is also very easy.

- Multistage Turbo Blower

A multistage blower ranges from 30 to 3000 HP. It is mainly designed for operating with variable frequency drive control. It offers superior performance and it is adaptable both for air as well as for hazardous gas in pressure or vacuum applications. It has longer bearing life and is 5-7 % more energy efficiency. It provides a high level of reliability and is adaptable in all kinds of environment. It provides oil-free compression and thus its maintenance cost is also low.

How Turbo Blowers are superior to the traditional Blowers?

Turbo Blowers are highly superior to the traditional blowers in a variety of ways and some of them are discussed as follows:

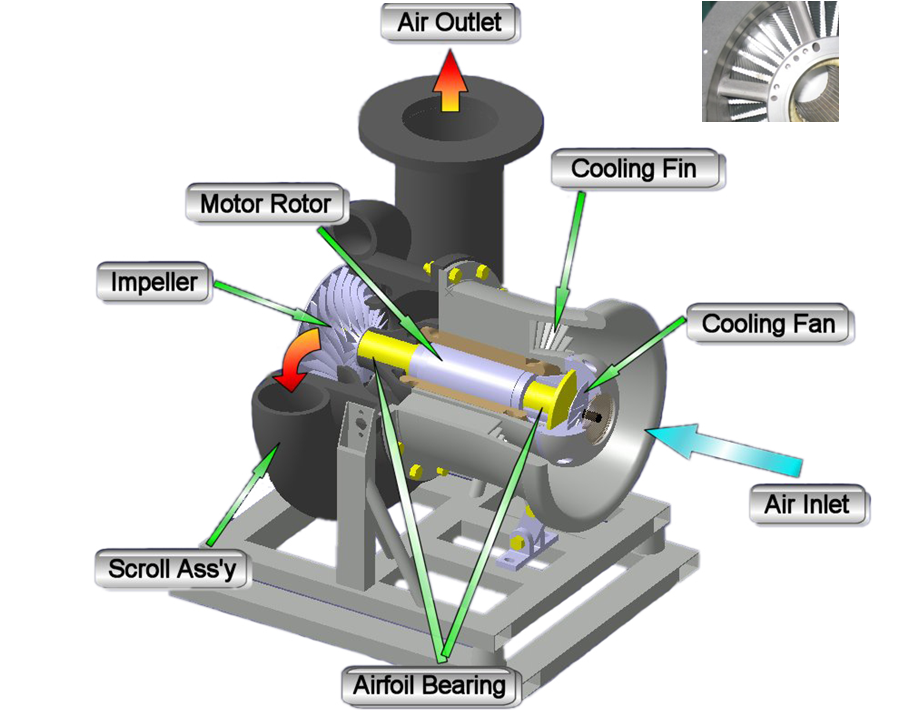

- Highly energy efficient: Turbo Blowers is a permanent magnet synchronous and they use a high-speed motor that has accurate speed control. Hence these kinds of blower are highly energy efficient than that of the traditional blower. Apart from that, it also provides zero power transmission loss. It has direct coupled impeller on the motor shaft and as such it does not come up with any hearing loss.

- Low noise and environmental friendly: Turbo Blowers do not produce any kind of vibrations and it also does not need any kind of oil lubrication. As a result unlike the traditional blowers, it produces low noise and is highly environmentally friendly.

- Easy installation process: Unlike the traditional blower, Turbo Blowers do not require any kind of additional lifting device or special foundation for its installation. You can use it immediately after a local adaption and startup procedure is completed. Thus it involves simple plug and plays the installation process.

- Minimal maintenance: As compared to the traditional blowers Turbo Blowers are require low operational and maintenance cost. It does not require any kind of sensitive electronics for controlling the bearing functionality.

- Quick and convenient service: Turbo bowlers provide quick and convenient service as it comes up with a modular design. It has a small footprint having some easy access point which you will not get in the traditional blower.

These are the reasons why turbo blowers are very demanding in the market and are now highly used in all kind of manufacturing industries.

Share your thoughts