The technology is developing at a fast pace, causing changes in the working methods of the graphics. And to keep their business competitive and profitable, large and small graphics entrepreneurs should be aware of the latest developments in their marketplace, particularly in software resources and printing machines. Some new printing innovations (that are worth paying attention to) include high-speed on-demand digital printing, three-dimensional printing, hybrid printing processes and increase the efficiency of digital printing workflows. Even the cheapest brochure printing available online can produce excellent quality.

[tmh_article_ads]

Development in digital inkjet printing

Offset printing has long been an industry standard, but demand has fallen steadily due to longer process workflow times and a lack of cost-effectiveness. As commercial inkjet printers have become faster, more reliable and of higher quality, these machines are quickly replacing offset printers. High-quality and professional-grade inkjet printers are now able to render text at up to 4,000 words per minute, and the speeds for images and graphics are not far behind.

Digital printing technology is not only faster: it can also make the designs much more elaborate than the print professionals could have done in the recent past. Variable surface finishes can now be printed on the same project, and three-dimensional graphics designs can now be printed with more realistic depth. These creative possibilities allow designers to put together attractive designs with fewer limitations than they would have encountered with offset printing.

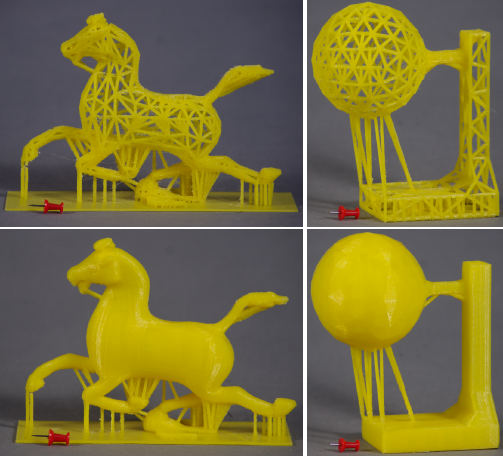

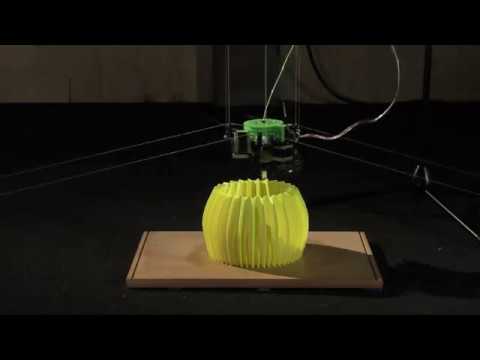

The emergence and growth of 3D printing

This innovation attracted significant attention in the printing and design industries, and many print business owners took note of the creative and manufacturing possibilities. Large-scale commercial 3D printing also has the potential for innovations in the field of trade show specialties, with applications for any type of professional or company needing, for example, a prototype or pre-analysis mockup, such as medical labs, vehicles, aerospace companies, agribusiness, etc.

As we have already touched on other opportunities here, the plastic industry has been increasingly adopting 3D printing for the development of injection molds. After all, the technology enables companies to reduce prototyping time and increase their competitive advantage through the development of costly molds and tools. 3D injection molded injection wells are used as functional prototypes so that companies can develop and perform validation tests on these wells before machining the final molds and thereby save time and cost since the machining of the mold is an expensive and time-consuming process. In addition, making adjustments to the machined mold is cumbersome and may not yield satisfactory results in terms of part design. In addition, companies in the plastics industry can print the wells more than once, making the necessary adjustments, until final validation arrives. It is even possible to inject a short run of pieces into the final material itself using the printed mold (the number of parts injected will depend on the type of material, cycles, and conditions of temperature and pressure at which the mold will be subjected).

Software innovations for print companies

There is much new graphic design software and they have a wider range of features and tools, allowing for easier workflows, better file compatibility, and more collaboration between designers in different geographic locations. Some new printing software includes three-dimensional tools that allow designers to create parts and objects without the need for extensive engineering knowledge.

Even two-dimensional printed designs can now be completed with more economical methods, thanks to the greater flexibility of modern design software. The need for film media and offset printing machines is steadily declining as more of the same results can be realized electronically with faster, more economical software workflows. The learning curve of these design sets may be a bit slower at the beginning for new users, but the owners of the printing companies who invest in them are seeing the benefits in terms of higher quality of the design in less time.

Hybrid Printing Technologies

Despite the fast pace of technological innovation, printing and design companies do not have to switch to purely digital processes overnight. They can, instead, integrate digital and offset processes, thanks to the automation of computer print sheets. This new innovation gives the ability to send image files to plates (electronic ones). The technology used is quite similar to those in desktop scanners. Due to improvements in these printing plates, hybrid processes can also accommodate more complex printing projects with many different colors and finishes. Along with fingerprints, software improvements and 3D developments, these innovations in the printing industry are helping this field evolve to meet the demands of the 21st century.

The progress of printing technology has brought many conveniences to all of us and as technology continues to grow day by day, we may see more sophisticated in the not too distant future.

Share your thoughts